NEW PLANTS

NEUANLAGEN

We offer our customers complete solutions, starting with the selection of suitable processes, continuing with the planning, manufacture, completion, and installation of turnkey systems with their associated residual wastewater treatment.

Every FKG Galvano system is always unique, and we aim to ensure that it runs for many years. The foundation for this is a design based on many years of expertise, solid construction, and high-quality workmanship. When you choose a system from FKG, you always can be sure you are getting the highest quality. The long service life of our systems in operation is the best proof of this - many of which have been in operation for more than 30 years.

No matter which process our customers choose, GS, WX, GX, etc., we have the perfect solution for every task. Be it profiles or façade parts for architecture with organic or even interference colouring. We're the right partner for you.

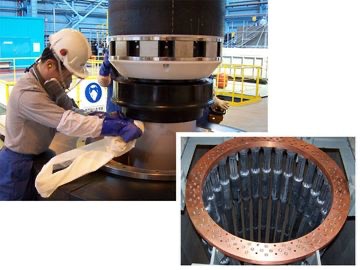

Conventional systems for hard chrome-plating machine parts. The systems are universally equipped for internal and external coating or with auxiliary anodes, depending on the requirements.

The systems usually consist of a row of containers for pre-treatment as well as the container equipment for hard chrome-plating and drying. The dimensioning of the system depends on the customer's workpiece sizes. The chrome area can be operated with little or no rinsing water, depending on the layer thickness.

Replacement solutions for (BK) chromic acid anodic coatings are becoming increasingly important. In the aerospace industry, this AIPI and NADCAP certified coating is already standard.

Our competence in this field is demonstrated by systems that are currently in use worldwide. Furthermore, the cyclical maintenance of these systems helps to always keep them permanently operational even during tough day-to-day operation.

Replacement solutions for (BK) chromic acid anodic coatings are becoming increasingly important. In the aerospace industry, this AIPI and NADCAP certified coating is already standard.

Our competence in this field is demonstrated by systems that are currently in use worldwide. Furthermore, the cyclical maintenance of these systems helps to always keep them permanently operational even during tough day-to-day operation.

Cleaning systems as individual systems for IBC containers, as pre-cleaning, with and without ultrasound as part of automatic systems. The FKG product range also includes stand-alone systems for parts cleaning and standard systems for special applications.

From "stands" for medical technology, elaborate pickling for "glass-metal joints" for the automotive industry to simple pre-treatment steps in manual and automatic systems. You can rely on us to implement your requirements in a practical way.

Regardless of the process (zinc phosphate, manganese phosphate, phosphate as an adhesive primer, etc.). We're here to provide you with the most suitable system technology. Our range of goods transport equipment includes goods carriers for individual parts with or without movement, drums as drum units or also in the form of container technology that can be latched and unlatched.

Directly or indirectly heated phosphating baths with or without continuous deslurrying. All techniques and processes are applied in our systems deployed worldwide.

Pre-treatment and equipment for non-destructive crack testing:

Damage to workpieces can be detected with the help of fluorescent penetrants. This requires cleaning; drying; applying penetrants; washing; drying and developing.

The processes up to the application of the developer can be fully automated.

FK Galvanotechnik GmbH

Brendstraße 9

75210 Keltern

Germany

Phone

+49 7236 9352-0

info@fkg-galva.de